Explore Exceptional Quality in Vacuum Based Bearings

Discover the high-quality vacuum-based bearings that revolutionize precision and performance across industries. Learn how our advanced technology can enhance your operations.

- Home

- Section

- Subsection

- Current Page

Introduction to Vacuum Based Bearings

Discover the unparalleled precision and reliability of vacuum-based bearings. These advanced bearings operate on the principle of vacuum and air pressure, ensuring wear-free sliding and frictionless motion. Ideal for high-precision applications in industries such as semiconductor manufacturing, aerospace, and metrology, our bearings guarantee stable, noise-free operation. With superior load capacity and minimal maintenance requirements, they are essential for enhancing performance and efficiency in your machinery.

Essential Features of Vacuum Based Bearings

Corrosion Resistance for Longevity

Vacuum-based bearings are designed to resist corrosion, ensuring a longer operational lifespan even in harsh environments. This feature is crucial for applications in industries like aerospace and semiconductor manufacturing.

Low Friction for Enhanced Precision

These bearings offer low friction, resulting in smooth and precise movements. This is essential for high-precision tasks in metrology and robotics, where accuracy is paramount.

Wear-Free Sliding for Reduced Maintenance

Experience wear-free sliding with vacuum-based bearings, which eliminates the need for frequent maintenance. This feature is particularly beneficial in cleanroom environments and scientific research where contamination must be minimized.

Stable Operation for High-Performance Tasks

The stable operation of vacuum-based bearings ensures consistent performance, making them ideal for high-speed and heavy-load applications. Industries such as aerospace and semiconductor manufacturing greatly benefit from this stability.

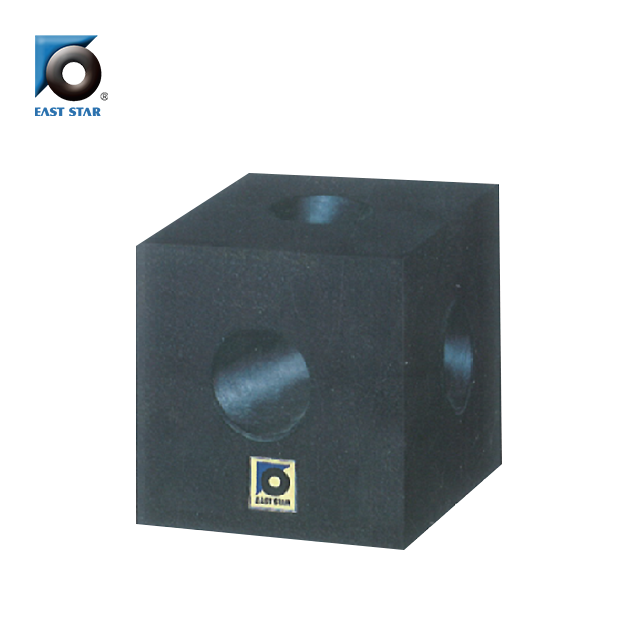

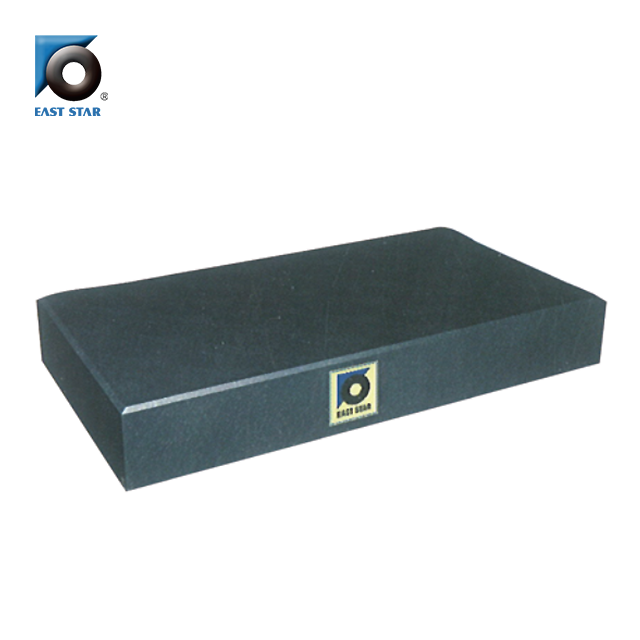

Our Vacuum Based Bearing Products

Explore our range of vacuum-based bearing products, each meticulously designed for precision and efficiency. Our offerings include various certified and compliant models, ideal for applications in semiconductor manufacturing, aerospace engineering, and high-precision metrology. Click on each product to view detailed specifications and application scenarios, ensuring you find the perfect solution for your needs.

Technical Specifications of Our Bearings

Discover the comprehensive technical specifications of our vacuum-based bearings. Explore detailed parameters including material composition, dimensions, and load capacity to make an informed purchasing decision.

| Specification | Details |

|---|---|

| Material | High-precision Granite |

| Dimensions | 200mm x 200mm x 50mm |

| Load Capacity | Up to 500 kg |

| Operating Pressure | 0.5-1.0 MPa |

| Accuracy | ±0.001 mm |

| Surface Finish | Ra 0.2 µm |

| Temperature Range | -20°C to 80°C |

| Maintenance | Minimal, wear-free sliding |

Frequently Asked Questions

Our detailed FAQ section addresses common questions about vacuum air bearings, helping users understand product features, usage methods, and after-sales service. This module provides clear and concise information, ensuring you have everything you need to make informed decisions about our precision instruments.

Vacuum air bearings offer numerous advantages, including frictionless motion, wear-free sliding, and enhanced precision. These bearings eliminate physical contact, reducing maintenance and extending lifespan. Additionally, they provide stable and consistent motion, making them ideal for high-precision applications in various industries such as semiconductor manufacturing and aerospace.

Vacuum air bearings enhance precision by providing a smooth, frictionless surface for movement. This eliminates mechanical contact, reducing the risk of errors and wear. The stable motion ensures accurate measurements, which is crucial in industries like metrology and semiconductor manufacturing, where even minor deviations can significantly impact results.

Vacuum air bearings are widely used in industries requiring high precision and reliability. Key sectors include semiconductor manufacturing, aerospace, and metrology. They are also utilized in scientific research and development, particularly in experiments demanding precise motion control, such as nanotechnology and robotics.

Vacuum air bearings reduce maintenance costs by eliminating physical contact between moving parts, which minimizes wear and tear. This results in longer-lasting components and fewer replacements. The frictionless operation also reduces the likelihood of damage, ensuring consistent performance and lower overall maintenance requirements.

Vacuum air bearings can support heavy loads without compromising performance due to the absence of mechanical contact. The even distribution of air pressure across the bearing surface ensures stable and consistent lifting force, making them suitable for handling heavy equipment and machinery in various high-precision applications.

Vacuum air bearings contribute to noise reduction by eliminating mechanical contact and friction, resulting in quieter operation. This is particularly beneficial in environments where noise pollution must be minimized, such as cleanrooms and laboratories, enhancing the working conditions and maintaining a controlled environment.

Yes, vacuum air bearings are ideal for high-speed applications due to their frictionless nature. The absence of physical contact allows for smooth and precise movements, enabling faster positioning and improved accuracy. This makes them indispensable in industries like aerospace, robotics, and high-precision machining.

Vacuum air bearings ensure stable operation by evenly distributing air pressure across the bearing surface. This uniform lifting force eliminates deviations or wobbling during use, providing consistent and reliable performance. Such stability is crucial for applications demanding high precision and accuracy, such as in semiconductor manufacturing and metrology.

Vacuum air bearings are well-suited for cleanroom environments. Their frictionless design eliminates particle generation from mechanical wear, maintaining the cleanliness required in sensitive applications. This makes them ideal for industries like semiconductor manufacturing and scientific research, where contamination control is critical.

We offer comprehensive after-sales services for vacuum air bearings, including technical support, maintenance, and replacement parts. Our team of experts is available to assist with any issues, ensuring optimal performance and longevity of your equipment. We are committed to providing exceptional service to meet your needs.

About Us

At [Company Name], we pride ourselves on our impeccable reputation and outstanding performance in delivering tailored solutions to our clients. Our team of seasoned professionals brings a wealth of experience and expertise, ensuring that every project meets the highest standards of quality and customization. We are committed to sustainability, implementing eco-friendly measures in all our operations to minimize environmental impact. Our dedication to innovation and customer satisfaction has earned us the trust of a diverse clientele across various industries.

Our Service Offerings

Our Service Offerings provide comprehensive technical support and after-sales service, ensuring users experience quality, reliability, and value for money throughout their product usage.

Comprehensive Technical Support

Our expert team offers round-the-clock technical support to address any issues you may encounter, ensuring seamless product usage. We provide detailed guidance and troubleshooting to maintain optimal performance.

Efficient Calibration Services

We offer precise and efficient calibration services to ensure your equipment operates at peak accuracy. Our certified technicians use advanced tools to deliver reliable calibration results.

Timely Maintenance and Repairs

Our maintenance and repair services are designed to extend the lifespan of your equipment. We provide timely interventions and use genuine parts to guarantee longevity and reliability.

Customer Training Programs

We offer comprehensive training programs to help your team understand and effectively use our products. Our training sessions cover all aspects, from basic operations to advanced features.

Warranty and After-Sales Support

Enjoy peace of mind with our robust warranty and after-sales support. We ensure prompt responses to your queries and provide necessary replacements or repairs within the warranty period.

Regular Software Updates

Stay ahead with our regular software updates, enhancing the functionality and security of your equipment. We ensure your systems are always equipped with the latest features and improvements.

Dedicated Account Management

Our dedicated account managers provide personalized support, ensuring your specific needs are met. They offer tailored solutions and proactive assistance to enhance your overall experience.

User-Friendly Online Resources

Access a wealth of online resources, including manuals, FAQs, and video tutorials. Our user-friendly platform ensures you find the information you need quickly and easily.

Request a Quote

Ready to get a custom quote for your precision measurement needs? Fill out our quick contact form to receive a tailored quote or further product consultation from Jinan EAST STAR Precision Measure Co., Ltd. Act now to ensure you get the best solution for your specific requirements.