Discover Our Custom Vacuum-Based Bearing Systems and Our Factory Strength

Discover our custom vacuum-based bearing systems, designed for high precision and durability. Explore our factory's strength and capabilities in delivering top-quality solutions.

Unmatched Quality and Durability of Our Vacuum-Based Bearings

Experience the unmatched quality and durability of our Vacuum-Based Bearing System. Designed for high-performance and precision, these bearings are ideal for industries such as semiconductor manufacturing, aerospace, and metrology. Enjoy wear-free sliding, reduced maintenance, and enhanced productivity with our advanced technology.

Discover the Exceptional Features of Our Vacuum-Based Bearings

Frictionless Motion for Enhanced Precision

Our vacuum-based bearings provide frictionless motion, eliminating wear and tear. This ensures enhanced precision and accuracy in your applications, making them ideal for high-performance machinery.

Exceptional Durability and Longevity

Designed for durability, our vacuum-based bearings offer a longer lifespan with reduced maintenance needs. The absence of mechanical contact ensures consistent performance over extended periods.

High Precision and Stability

Achieve high precision and stable operation with our vacuum-based bearings. The uniform distribution of air pressure ensures consistent motion, eliminating deviations and ensuring optimal performance.

Superior Craftsmanship and Standards

Our bearings are manufactured with the highest standards and meticulous craftsmanship. This commitment to quality ensures that each bearing meets the stringent requirements of various high-precision applications.

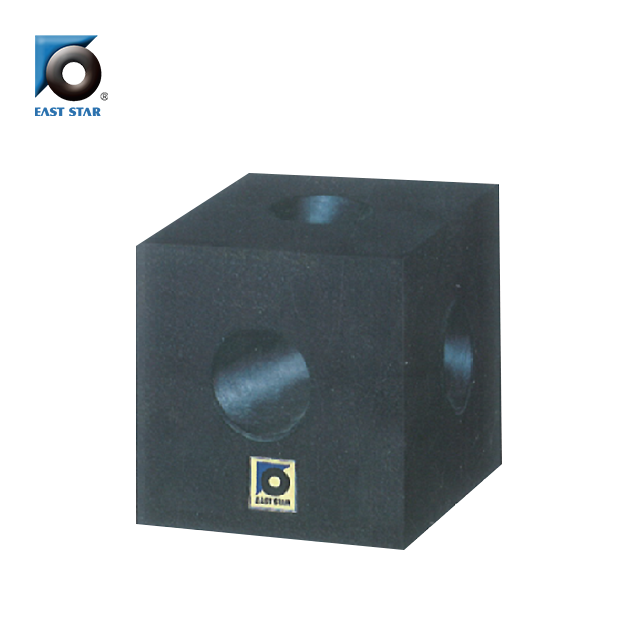

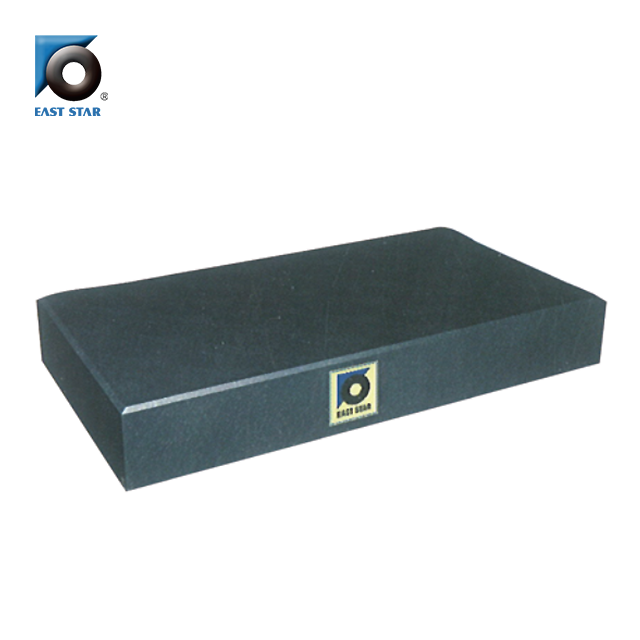

Explore Our Range of Vacuum-Based Bearings

Explore our range of vacuum-based bearings, showcasing various models with detailed images and descriptions. Our bearings are designed for high-precision applications in industries such as semiconductor manufacturing, aerospace, and metrology. Each product listing includes comprehensive technical parameters to help you select the perfect bearing for your needs. Discover the unmatched accuracy, reduced maintenance, and enhanced efficiency that our vacuum-based bearings bring to your advanced machinery and instrumentation.

Hear What Our Customers Say About Our Bearing Systems

Emily Johnson

The bearing systems from this company have significantly improved the efficiency of our machinery. We have experienced fewer breakdowns and increased productivity. Highly recommend their products!

Michael Smith

Excellent customer service and reliable products. The bearings we purchased have been performing flawlessly for over a year now. We are very satisfied with our decision to choose this company.

Sarah Lee

We switched to these bearing systems six months ago, and the difference is night and day. Our equipment runs smoother and requires less maintenance. We are extremely pleased with the results.

David Brown

The durability and performance of these bearings are impressive. They have exceeded our expectations and have become an integral part of our operations. Great value for the investment.

Jessica Williams

After trying several other brands, we finally found the perfect bearing systems here. The quality and reliability are unmatched, and the support team is always ready to assist. Highly satisfied!

Robert Martinez

These bearing systems have been a game-changer for our production line. The reduced downtime and enhanced performance have positively impacted our bottom line. Strongly recommend!

Frequently Asked Questions About Our Bearings

Our FAQ section provides detailed answers to common questions about purchasing and using vacuum-based bearing systems. This resource is designed to help users understand the applications, benefits, and operational aspects of air bearings, ensuring an informed and smooth experience.

Air bearings offer frictionless motion, enhanced precision, and reduced maintenance. They provide stable and consistent operation, support heavier loads, and minimize noise. These benefits make them ideal for applications in semiconductor manufacturing, aerospace, and metrology.

Air bearings eliminate physical contact between moving parts, reducing the risk of contamination and wear. This ensures precise and stable movement, which is crucial for the delicate processes involved in semiconductor manufacturing, leading to higher accuracy and better product quality.

Key industries include semiconductor manufacturing, aerospace, and metrology. Air bearings are also used in scientific research, robotics, and high-precision machining. Their ability to provide frictionless, stable, and precise motion makes them indispensable in these fields.

Vacuum-air bearings eliminate mechanical contact, reducing wear and tear. This leads to longer equipment lifespan and lower maintenance costs. The absence of friction also ensures smoother operation, contributing to the overall durability and reliability of the equipment.

Yes, air bearings are ideal for high-speed applications due to their frictionless nature. They enable smooth and precise movements, which are essential for high-speed operations in industries like aerospace, robotics, and precision machining, ensuring optimal performance and accuracy.

In metrology, air bearings are used in high-precision measuring instruments such as coordinate measuring machines (CMMs) and optical profilometers. They provide smooth and accurate movement, enabling precise measurements of objects and surfaces, which is critical for quality control and research.

Air bearings operate without mechanical contact, significantly reducing friction and noise. This makes them particularly advantageous in environments where noise pollution needs to be minimized, such as cleanrooms, laboratories, and other sensitive industrial settings.

Yes, air bearings can support heavier loads due to the absence of physical contact. This makes them suitable for applications requiring the handling of heavy equipment or machinery, ensuring stable and consistent performance without compromising on accuracy or efficiency.

Get Your Custom Vacuum-Based Bearing Today!

Ready to enhance your filling solutions with our custom vacuum-based bearings? Contact us today to discuss your specific needs and get personalized assistance from our experts. Fill out the form below to start your journey towards optimized packaging machinery.