Precision Granite Measuring Tools for Businesses

Discover high-quality Granite Measuring Instruments that ensure precision and reliability for your business needs. Enhance your accuracy with our superior tools.

Granite Measuring Tools for Business Customization

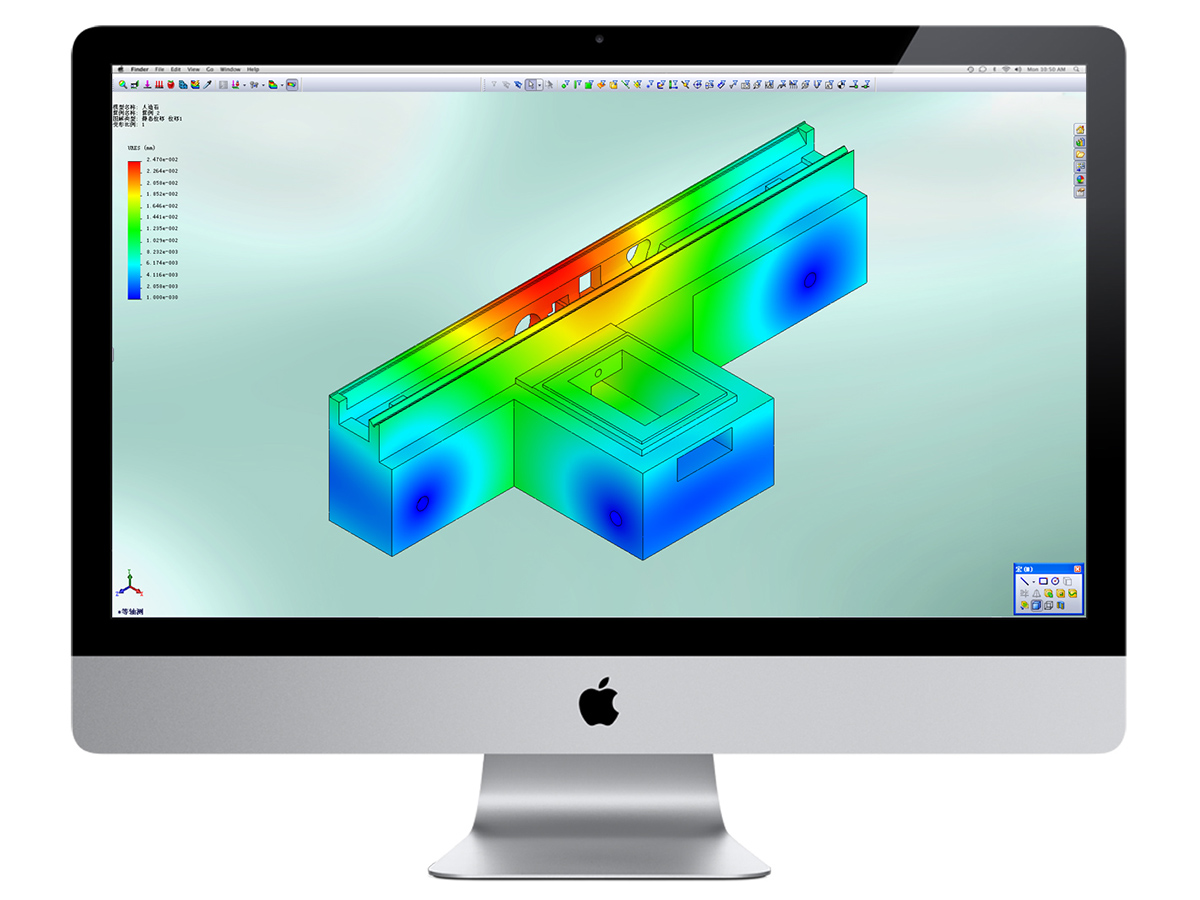

Discover the unparalleled accuracy and stability of Granite Measuring Instruments, essential for precision engineering. Crafted from high-quality granite, these tools excel in mechanical processing, laboratory research, and quality control. Their thermal stability and resistance to wear ensure consistent, reliable measurements, making them indispensable in various industrial applications.

Precision Granite Measuring Tools for Businesses

Discover the unparalleled precision and durability of our Granite Measuring Instruments, crafted from natural granite and designed with advanced manufacturing techniques. Experience high precision, low thermal expansion, wear resistance, and corrosion resistance.

High Precision Measurement

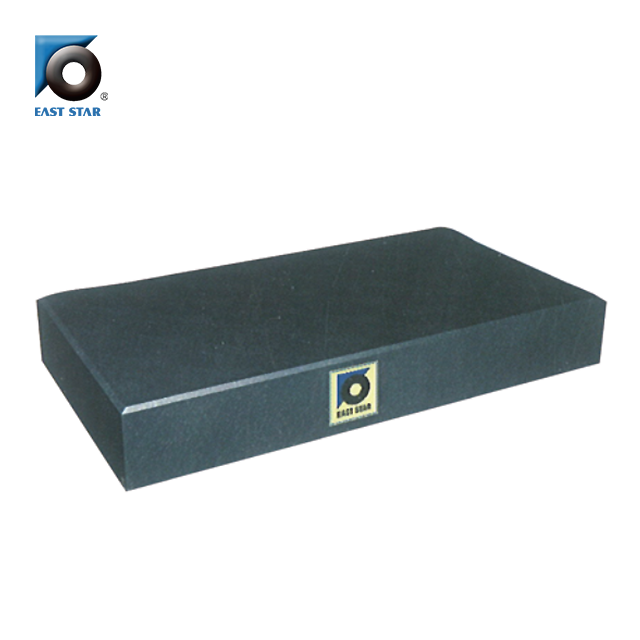

Our granite measuring tools offer exceptional accuracy, ensuring precise measurements for critical applications. The natural granite material provides a stable and reliable surface, ideal for ultra-precision machine tools and instruments.

Low Thermal Expansion

With a low thermal expansion coefficient, our granite instruments maintain their accuracy even under varying temperatures. This stability is crucial for maintaining consistent measurements in demanding environments.

Superior Wear Resistance

Engineered for longevity, our granite measuring tools resist wear and tear, ensuring long-term reliability. The hard texture of natural granite makes it an ideal material for precision measurement surfaces.

Corrosion Resistance

Our granite instruments are highly resistant to corrosion, making them suitable for use in various industrial environments. This durability ensures that your tools remain accurate and functional over time.

Precision Granite Measuring Tools for Businesses

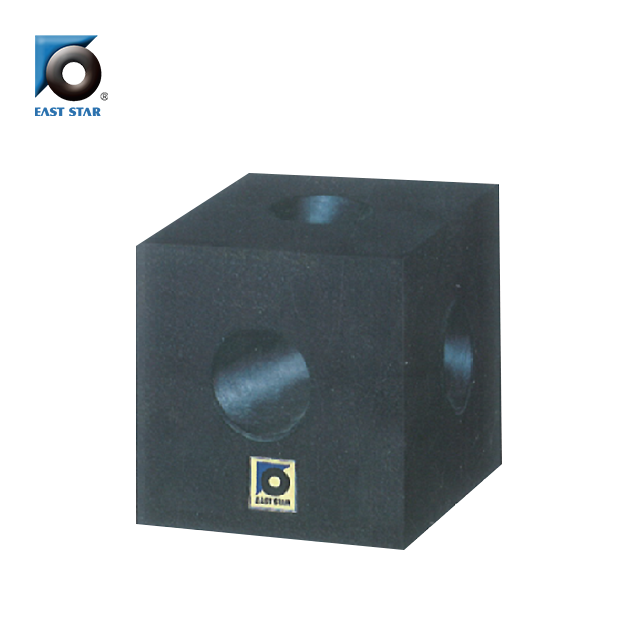

Discover our extensive range of Granite Measuring Instruments, including surface plates, squares, straight edges, parallels, and V-blocks. Each product is meticulously crafted to ensure precision and reliability. Our surface plates provide a stable reference plane for accurate measurements, while our squares and straight edges guarantee perfect right angles and straight lines. Parallels and V-blocks are essential for secure positioning and alignment of workpieces. Explore the specific uses and benefits of each instrument to enhance your measurement accuracy and efficiency.

Granite Measuring Tools for Business Custom Solutions

Discover the diverse application scenarios of Granite Measuring Instruments, ensuring precision and reliability across various industries. From aerospace to automotive manufacturing and medical equipment production, our instruments are designed to meet the highest standards of accuracy and performance.

Real Feedback on Granite Measuring Tools from Businesses

Shanghai Paixie Packaging Machinery Co., Ltd.

"Shanghai Paixie Packaging Machinery Co., Ltd. has been using Granite Measuring Instruments for over a year now, and the results have been outstanding. The precision and reliability of these tools have significantly improved our production accuracy, ensuring that our packaging machinery meets the highest standards. The benefits of using Granite Measuring Instruments are evident in our enhanced product quality and reduced maintenance costs. We highly recommend these instruments to any business looking to achieve superior measurement accuracy."

Jinan EAST STAR Precision Measure Co., Ltd.

"Our experience with Granite Measuring Instruments has been nothing short of exceptional. The tools have provided us with unparalleled precision, which is crucial in our industry. The positive experiences we've had with these instruments have translated into better product consistency and customer satisfaction. The benefits of using Granite Measuring Instruments are clear, and we are confident in their ability to deliver reliable and accurate measurements."

Suzhou Wujiang Fenhu Economic and Technological Development Zone

"Granite Measuring Instruments have become an integral part of our quality control process. The accuracy and stability they offer have allowed us to maintain high standards in our manufacturing operations. The positive experiences we've had with these instruments have reinforced our trust in their capabilities. The benefits of using Granite Measuring Instruments are undeniable, and we are pleased with the improvements in our production efficiency and product quality."

Fenhu Economic and Technological Development Zone

"Since incorporating Granite Measuring Instruments into our workflow, we've seen a marked improvement in our measurement accuracy and overall production quality. The positive experiences we've had with these tools have been instrumental in achieving our operational goals. The benefits of using Granite Measuring Instruments are evident in our reduced error rates and enhanced product reliability. We highly recommend these instruments to any business seeking precision and consistency."

Granite Instruments: Your B2B Custom Solutions FAQs

Our granite instruments are known for their high density, compressive strength, and low thermal expansion. For instance, Jinan Black Granite has a density of 3.07 g/cm³ and a compressive strength of 262.2 MPa. These properties ensure stability and precision in various industrial applications.

Regular maintenance of granite instruments involves cleaning with a soft cloth and mild detergent to remove dust and debris. Avoid using abrasive materials that can scratch the surface. Periodic calibration checks are also recommended to ensure ongoing accuracy and performance.

Calibration of granite measuring instruments involves comparing the instrument's measurements with a standard reference. This process should be performed by qualified technicians using certified calibration equipment. Regular calibration ensures the instrument's accuracy and reliability over time.

Yes, we offer extensive customization options for our granite measuring instruments. You can specify dimensions, surface finishes, and additional features such as threaded inserts or dowel pin holes. Our design flexibility allows us to meet your specific requirements and application needs.

Granite offers several advantages over other materials, including superior vibration damping, thermal stability, and cost-effectiveness. It reduces vibration more effectively than aluminum, cast iron, or steel, and has a lower thermal expansion coefficient, ensuring consistent performance in varying temperatures.

To request a quote, please contact our sales team with your specific requirements, including dimensions, material preferences, and any additional features. Our team will provide a detailed quote and assist you throughout the customization process to ensure your needs are met.

Yes, our granite instruments comply with international standards such as ISO 9001 and UKAS. We ensure that all our products meet stringent quality and performance criteria, providing you with reliable and accurate measuring solutions.

We use various types of high-quality granite, including Jinan Black, South African Black, and Indian Black. Each type has unique properties, such as density and compressive strength, allowing us to select the best material for your specific application.

Granite's low thermal expansion coefficient minimizes dimensional changes due to temperature fluctuations. This thermal stability ensures that our measuring instruments maintain their accuracy and precision, even in environments with varying temperatures.

Our granite measuring instruments are widely used in industries such as precision manufacturing, optical instrumentation, and the LCD industry. They are ideal for applications requiring high accuracy, stability, and durability, making them a preferred choice for many industrial sectors.

Connect with Our Granite Measuring Solutions

Discover the precision and reliability of our Granite Measuring Instruments. Contact us today to learn more, request a quote, or schedule a consultation with our experts. Elevate your measurement accuracy with Jinan EAST STAR Precision Measure Co., Ltd.