Hydrocasting is a modern manufacturing technique that is gaining increasing attention across various industries due to its ability to produce high-strength, precision-engineered parts with superior surface finishes. As more engineers, designers, and industrial decision-makers explore alternatives to traditional materials like steel, cast iron, and aluminum, one term that frequently appears alongside hydrocasting is Mineral Casting. This article explores the concept of hydrocasting, its synergy with mineral casting, and how this combination plays a vital role in high-precision machine building, especially in sectors like automotive, electronics, aerospace, and heavy machinery.

Hydrocasting, also known as hydrodynamic casting, is a process that involves shaping materials—typically composite mixtures or resins—using hydraulic pressure. The liquid material is injected into a mold cavity, where it takes the desired form under pressure. Unlike traditional die casting or sand casting, hydrocasting utilizes fluid dynamics to eliminate air pockets and ensure uniform material distribution.

This method can be applied to various base materials. However, when used in combination with mineral casting, it offers superior mechanical damping properties, precision, and stability.

Before diving deeper into the hydrocasting process, it's essential to understand what mineral casting is. Sometimes referred to as polymer concrete or epoxy granite, mineral casting is a composite material made from:

Gravel or crushed stone aggregates

Quartz sand

Resins or polymers as binders

Fillers such as fly ash or other fine powders

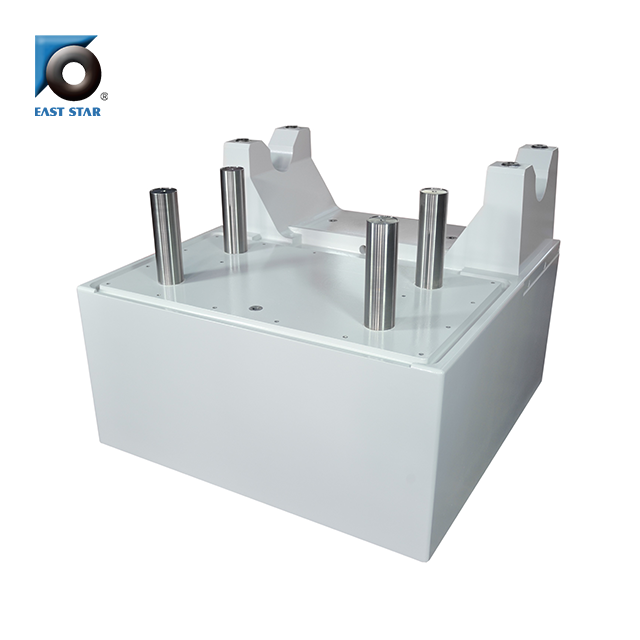

This combination yields a material that is stronger and more vibration-resistant than traditional metal-based options. Mineral casting is widely used for building machine beds, frames, and base structures due to its outstanding performance in precision engineering.

Using hydrocasting techniques with mineral casting opens a new dimension in the manufacturing of high-performance parts. The advantages include:

Higher dimensional stability

Exceptional vibration damping

Improved surface finish

Faster production cycles

More complex geometries possible

Sustainability through energy savings

The fluid pressure in hydrocasting ensures the mineral-filled resin flows uniformly into every crevice of the mold, reducing the need for post-processing or machining. This is a major advantage when compared with traditional metal casting.

| Property | Mineral Casting | Cast Iron |

|---|---|---|

| Vibration Damping | Up to 10x better | Lower damping |

| Thermal Expansion Coefficient | Low | Moderate |

| Density | Lower | Higher |

| Corrosion Resistance | High | Requires coating or treatment |

| Machinability | Often no post-machining needed | Requires extensive machining |

| Weight | Lighter | Heavier |

| Sustainability | Made from recyclable materials | Higher environmental impact |

Machine Tool Bases: CNC machines and high-speed milling machines benefit from the excellent vibration-damping and stability offered by mineral casting.

3D Printer Frames: The demand for lightweight, rigid, and stable printer frames has made mineral casting a preferred choice.

Medical Equipment: MRI machines, CT scanners, and lab automation tools require precise components with zero tolerance for vibration.

Electronics Manufacturing: Pick-and-place machines and PCB drills perform better when housed in mineral cast frames.

Metrology and Measurement: CMM (Coordinate Measuring Machines) benefit from the dimensional stability of mineral cast bases.

Let’s examine how mineral casting enhances hydrocasting outcomes:

Traditional materials like cast iron transmit vibrations during machining operations. This reduces tool life and compromises part quality. Mineral casting materials, when hydrocast, absorb and dampen these vibrations significantly, ensuring better accuracy and finish.

Machines often heat up during operations. Mineral cast structures exhibit low thermal expansion, keeping parts aligned and precision intact even under temperature variation.

Thanks to hydrocasting, mineral casting can be molded into complex geometries with integrated cable channels, fluid circuits, or mounting points—reducing the need for assembly and machining.

Though initial mold costs may be higher, hydrocast mineral cast components require less machining, less assembly, and lower maintenance—drastically cutting life-cycle costs.

Mineral casting uses recycled stone and industrial waste materials as fillers. Combined with energy-efficient hydrocasting, the overall carbon footprint is significantly reduced.

| Feature | Mineral Casting | Metal Casting (Iron/Aluminum) |

|---|---|---|

| Post-Machining Requirement | Minimal | High |

| Mold Cost | Moderate to High | Low to Moderate |

| Tool Life | Long (due to damping) | Shorter |

| Surface Finish Quality | Excellent | Requires polishing |

| Material Cost | Moderate | Varies |

| Production Speed | Fast (with hydrocasting) | Moderate |

| Complexity of Parts | High (with hydrocasting) | Limited |

Recent years have seen innovations pushing the boundaries of hydrocasting and mineral casting technologies. Key trends include:

Integrating sensors directly into mineral cast parts during the hydrocasting process allows for real-time vibration monitoring, structural health diagnostics, and predictive maintenance.

Some manufacturers are experimenting with combining 3D printing and hydrocasting—especially for mold design and rapid prototyping of mineral cast parts.

Hydrocasting with mineral casting uses less energy than traditional foundries and emits fewer greenhouse gases. This aligns with the growing demand for green manufacturing practices.

While mineral casting inherently resists corrosion, adding functional coatings (thermal insulation, electrical shielding) during hydrocasting further boosts product performance.

When evaluating hydrocasting or mineral casting partners, consider:

Experience with complex hydrocasting projects

In-house mold design and customization capabilities

Support for integrated mechanical, electrical, or pneumatic systems

Track record in your specific industry

ISO certifications and quality assurance protocols

Mineral casting is a material, while hydrocasting is a process. Hydrocasting can be used to shape mineral casting mixtures under fluid pressure to produce precision parts with excellent structural integrity.

In applications that require vibration damping, thermal stability, and design flexibility, mineral casting is superior to traditional metal casting. However, for high-temperature or high-impact applications, metals may still be preferable.

Yes. With hydrocasting, very large and complex machine bases and housings can be produced with high precision.

While initial mold creation can be costly, mineral casting reduces total cost of ownership through lower machining, better tool longevity, and longer equipment life.

Absolutely. Most mineral cast materials are composed of recycled stone aggregates and use less energy in production compared to metals.

Hydrocasting is reshaping how modern manufacturers approach high-precision component production. When combined with mineral casting, it offers unmatched benefits in terms of vibration damping, thermal stability, design freedom, and sustainability. As industries increasingly seek smarter, more efficient, and environmentally responsible materials, hydrocast mineral casting will continue to emerge as a cornerstone in advanced manufacturing.

Whether you're an engineer designing a next-gen CNC bed or a procurement manager sourcing medical equipment frames, understanding the synergy between hydrocasting and mineral casting is key to making informed, future-proof decisions.

Copyright © 2023 Jinan EAST STAR Precision Measure Co., Ltd. All rights reserved. | Sitemap | Privacy Policy | Support By Leadong