Views: 0 Author: Site Editor Publish Time: 2025-07-24 Origin: Site

Granite measuring tools mainly include flat plates, right angle rulers, square rulers, flat rulers, square boxes, V-shaped blocks, parallel gauges, etc. The following are their specific introductions:

1. Granite platform

Introduction: Made from high-quality natural granite through mechanical processing and manual precision grinding, it is a reference plane used for various inspection work.

Application scope: Suitable for machine tool mechanical inspection measurement benchmarks, checking the dimensional accuracy or behavioral deviation of parts, and can also be used for precision marking. It is an indispensable basic measurement tool in industries such as mechanical manufacturing, aerospace, and automotive manufacturing.

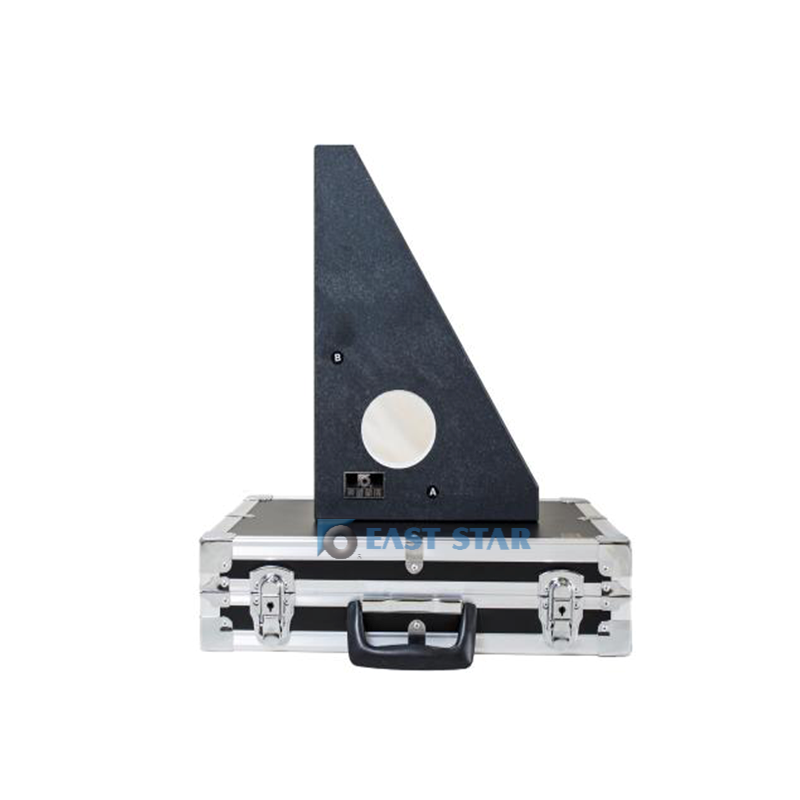

2. Granite square ruler

Introduction: Black luster, precise structure, uniform texture, good stability, high strength, high hardness, able to maintain high precision under heavy load and general temperature.

Application scope: It is mainly used to detect the vertical deviation of workpieces and the relative position of mechanical components. It also has auxiliary marking function and is commonly used in machine tool equipment inspection, aerospace component inspection, automotive component installation and positioning, and other fields.

3. Granite square ruler

Introduction: Also known as marble square ruler, the accuracy level is divided into 00 level and 0 level.

Application scope: It is mainly used to detect the parallelism, perpendicularity, and flatness of workpieces and machine tool guides, and can be used for grinding and processing. It is widely used in the detection of instruments, precision tools, and mechanical parts.

4. Granite ruler

Introduction: Precision tools made by manual grinding have the characteristics of dense organizational structure, smooth and wear-resistant surface, and low roughness value.

Application scope: Used for measuring the straightness and flatness of workpieces and equipment installation, such as measuring the flatness and straightness of machine tool workbenches, guide rails, and precision work.

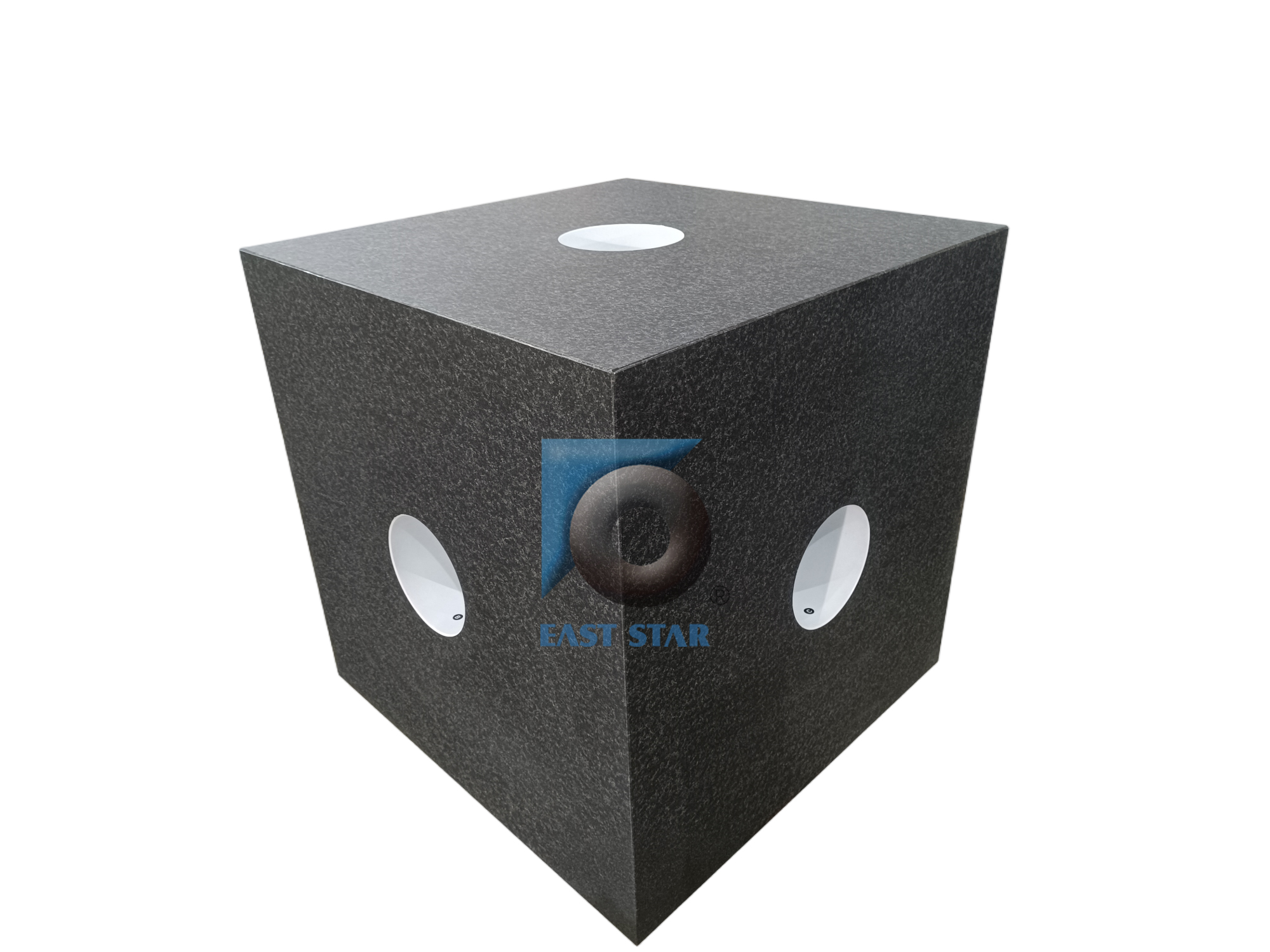

5. Granite square box

Introduction: It has a black luster, precise structure, uniform texture, good stability, high strength, and high hardness.

Application scope: Used for the measurement and inspection of the parallelism and perpendicularity of precision workpieces and mechanical parts, and can serve as a reference for positioning and measurement during mechanical processing and assembly.

6. Granite V-shaped block

Introduction: It is an ideal tool for detecting cylindrical objects and can process other surfaces with precision as needed.

Application scope: Mainly used for verticality and parallelism detection, and can be used as a 90 ° absolute measurement benchmark, commonly used for measuring and positioning shaft and cylindrical parts in mechanical manufacturing.

7. Granite Parallel Gauge

Introduction: Also known as marble parallel gauge, it is produced in pairs and used for straightness and parallelism detection.

Application scope: It can replace equal height pads and is mainly used to measure the parallelism of workpieces. It is a high-precision and precise reference measuring tool, which is an ideal reference surface for the inspection of instruments, precision tools, and mechanical parts.

Copyright © 2023 Jinan EAST STAR Precision Measure Co., Ltd. All rights reserved. | Sitemap | Privacy Policy | Support By Leadong